From dispensing microscopic beads of single-component materials in R&D settings to metering, mixing, and dispensing two-component materials in production environments, ESS can help you design and implement a system for dispensing sealants and adhesives that meets your needs.

Single-Component Dispense Solutions

The E-Flow iQ system dispenses single-component sealants and adhesives by metering directly from the drum and using an electric servo-driven motor and sensors to maintain consistent pressures from the drum to the applicator.

The PCF system provides consistent delivery of single-component sealants and adhesives through closed-loop feedback that constantly monitors changes in pressure and flow rate.

Graco UniXact automation systems, with their easy-to-use programming interfaces and precision dispensing, bridge the gap between research and development needs and mass production. ESS can help you select a UniXact system that is sufficiently sized for your workpiece, dispenses in the desired xyz-plane, and has a dispense valve (ambient or heated) that is optimized for your particular material.

Graco’s Advanjet jet valves dispense microscopic droplets of materials at a rate up to 300 droplets/s, droplets ranging from 5-500 nL, and lines between 400-1500 microns. The valves are modular with very few parts that are wetted and can be configured for your particular material and application needs.

The Graco 1k Ultra-Lite valve, available in manual and automatic versions, is designed to dispense a consistent bead and eliminate snake-heads and tails.

Two-Component Dispense Solutions

Graco’s PR70 benchtop system allows you to dispense two-component materials – using on-board or off-board feed systems – with material ratios of up to 24:1. The PR70 allows the preprogramming of a sequence of different shot sizes and is available in a variable ratio option.

Graco’s EFR system dispenses a continuous flow of two-component materials using mechanically linked pumps that ensure an on-ratio dispense. With the electric motor directly connected to the pumps and control architecture constantly monitoring and adjusting for the desired pressures, snakeheads and tails at the terminal ends of beads are eliminated.

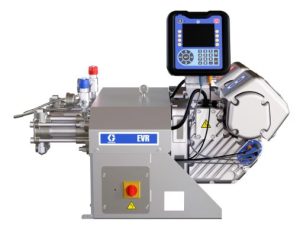

The Graco EVR metering system allows the operator to easily change ratios on the fly with electric variable ratio (EVR) metering. Graco’s high flow system can move up to 6,400 cubic centimeters (ccs) per minute, while flexing dispense ratios anywhere between 1:1 to 5:1 or 2:1 to 10:1. Such versatility allows manufacturers to mix, meter and dispense different materials with the same equipment.

The Graco HFR system provides precision dispensing of two-component foams, sealants, and adhesives requiring up to a 24:1 mix ratio. The HFR supports flow rates between 1 cc/s and 316 cc/s, and excels at dispensing high viscosity materials. Heated configurations are available.

The Graco F4-5, -55 system meters and mixes 1:1 ratio liquid silicone rubber materials, and provides a continuous dispense. Two flow meters carefully monitor fluid pressures to ensure on-ratio dispensing.

The Graco PR-X system is designed to meter, mix, and dispense materials that have a high viscosity, are abrasive, and are highly-filled. The system is fed from an external supply source or on-board cartridges depending on the material characteristics.

Graco UniXact automation systems, with their easy-to-use programming interfaces and precision dispensing, bridge the gap between research and development needs and mass production. ESS can help you select a UniXact system that is sufficiently sized for your workpiece, dispenses in the desired xyz-plane, and has a dispense valve (ambient or heated) that is optimized for your particular material.

The Graco PD44 fixed-ratio dispense valve dispenses small shots of two-component, low-viscosity sealants and adhesives. Positive displacement metering facilitates repeatable shots. Shot sizes are programmable or can be manually adjusted. Maintenance is minimized due to materials mixing only at the static mixer.

The Graco Voltex™ Dynamic Mix Valve has an electric motor that carefully controls the rotation of a disposable static mixer for precision mixing and dispensing. This valve can be integrated with Graco two-component metering systems such as the PR70 and EFR systems to provide a complete solution for your dispensing needs.

The Graco MD2 Dispense Valve is a reliable, low-maintenance valve that features adjustable snuff-back control. The valve is available in 1:1 or wide ratio configurations and can be actuated manually or integrated with an automation system.